Ingram Content Group’s global headquarters is located in LaVergne, TN, just outside of Nashville. Renovations at Ingram’s Lightning Source printing facility, also located in LaVergne, increased humidity demand and the existing Condair (Nortec) MLP RO system’s capacity fell short.

Lightning Source Printing Company

Importance of Precise Humidity Control in Printing Facilities

Location: LaVergne, TN

Precise humidification control is a must to maintain printing paper integrity for an efficient printing operation. Sheet and web roll paper are typically wrapped to stay in equilibrium with air at a 50% relative humidity level. If this humidity level is not maintained, the shape, dimensions, and physical properties of the paper could change and adversely affect the printing process. Printing industry presses must feed paper evenly at high speeds. If the facility’s relative humidity level drops below 40%, the movement of paper on paper and other surfaces (printing equipment) will generate electrostatic charges causing the surfaces to stick together and the paper to feed unevenly which could eventually lead to a jam in the printing press.

Renovations to the print floor at Lightning Source, including the addition of new printers and the expansion of the printing area real estate, increased the facility’s humidity demand. The calculated load demand could not be achieved by the existing Condair MLP RO humidification system.

Tom Barrow Company proposed the following two options to Lightning Source:

1) Max out the existing Condair MLP RO system’s capacity and fall short of the calculated humidity requirement.

OR

2) Install a new Condair MLP RO system with enough capacity to support the required additional load demand plus spare capacity for future renovations.

Lightning Source chose option two knowing the importance of maintaining an efficient environment.

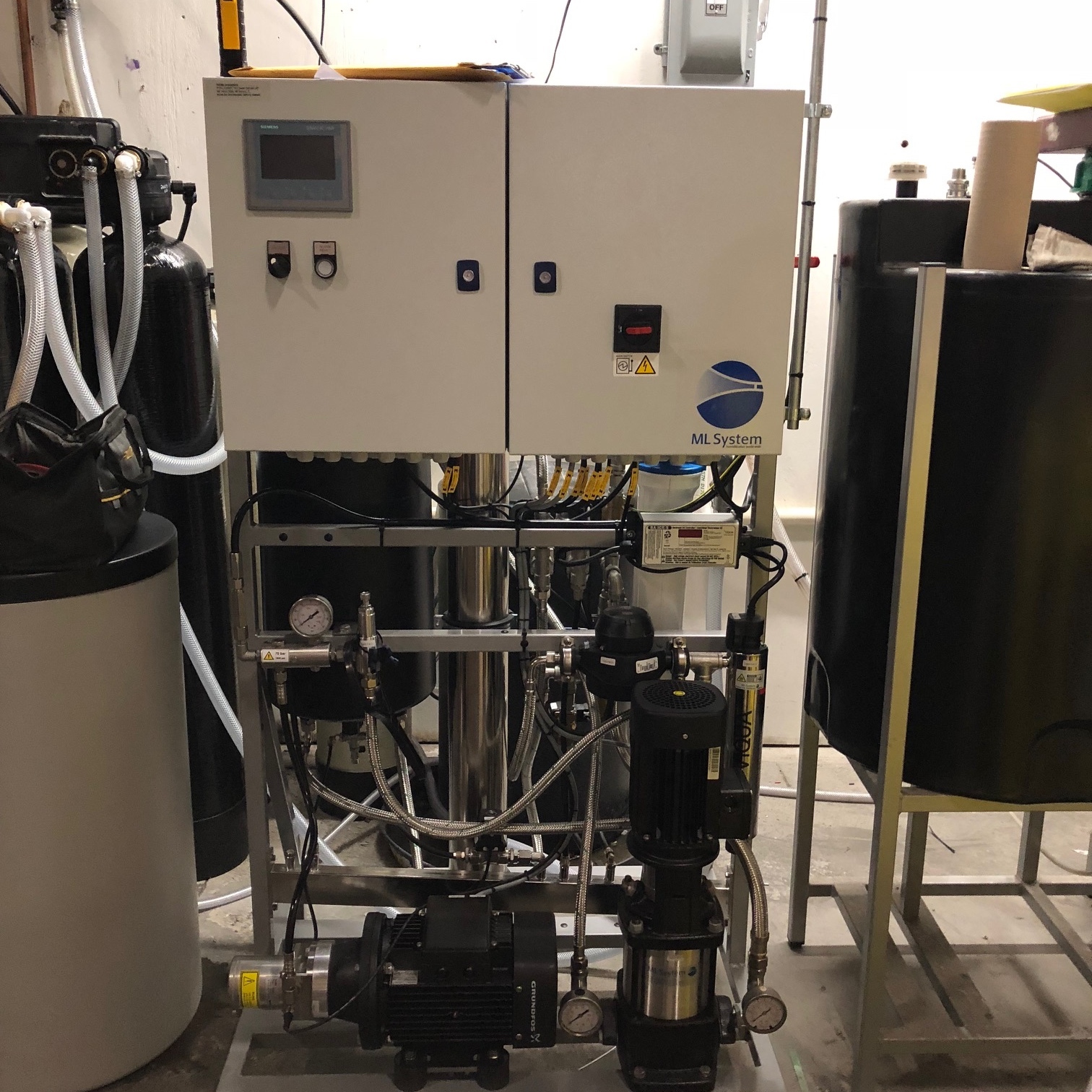

Condair’s MLP RO system utilizes RO water and a high-pressure pump with several components pre-assembled at the factory on a metal skid for easy shipment and install. RO water is a key hygienic component of the system. The Condair MLP RO system includes:

- Loose - carbon filter, twin alternating water softener, brine tank

- Factory mounted on skid - 5 micron filter, UV light, RO membrane, high pressure pump, control interface

The above water treatment components, in sequential order, are used to pretreat city water prior to misting discharge. Condair’s MLP RO system’s high-pressure pump delivers RO water through Condair’s ML Flex lines to several microscopic orifices – referred to as advanced atomized nozzles – which generate extremely fine spray of water droplets to ensure efficient evaporation and thus hygienic humidification production and free evaporative cooling. Humidity is delivered on demand based on a humidity sensor signal located in the center of the new zone.

During the initial walk through at Lightning Source, it was determined that we could use the natural draft of the new zone to our advantage by locating nozzles upstream from return air openings and allowing the draft to pull humidity across the space. The install took one week, and field labor included:

1. Customer provided 208 VAC disconnect switch

2. Condair expert piping city water - carbon filter - water softener - 5-micron filter on the skid assembly

3. Condair expert running nozzle lines throughout facility, close to the 33 ft. ceiling height, by use of a scissor lift

4. Condair expert mounting humidity sensor in the middle of the new zone and control wiring termination to control interface on skid assembly

5. Condair expert control calibration and system startup

Needless to say, the MLP RO skid assembly minimized field labor and Lightning Source was appreciative of the Condair turn-key solution.