Posted on February 15, 2024

Ensuring precise humidity control in pharmaceutical industry applications is a specialty of Fisair, where its experts specialize in psychrometry and the principles and benefits of humidity control across a wide range of sectors.

TBCo has extensive experience with humidity control, and Fisair’s technology provides for precise performance, as well as other benefits that save on time and costs related to installation and operation.

Dehumidifiers for the Pharmaceutical Industry

Hygroscopic products require moisture control to prevent deterioration or modification of their structure. This is best achieved using desiccant dehumidification which will ensure the air is kept below 20% RH with no difficulty, either in the process or in the room where the work area is located.

Fisair’s dehumidifiers give continuous air production, to create safe and stable environments, with minimum energy requirements.

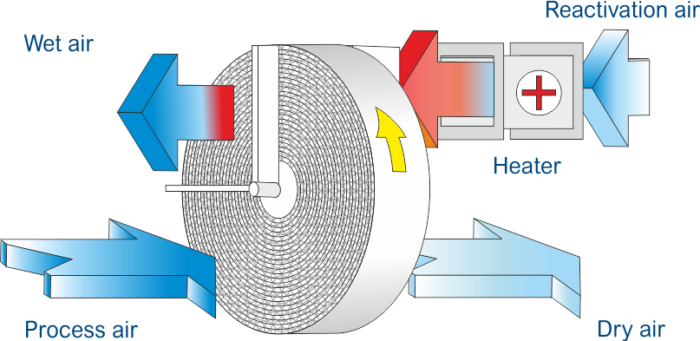

Under these specified conditions, desiccant dehumidification technology can achieve lower energy consumption than any other drying technologies, such as refrigeration systems, Fisair dehumidifiers base their operating principle on water vapor retention, using a unique, high-performance, silica gel desiccant rotor.

Installation is simple and an immediate reduction in overall energy consumption will be noticed.

- Storage and transport of raw materials: in this case, dry air is used to avoid the risk of bacterial proliferation or blockages of granulated material (silos and conveyor belts).

- Drying and coating processes: both in the drying process (whether by atomizing towers or fluid beds) and the coating process, product quality and production times are vital to ensure the constant high standard of production required.

- Encapsulation (blistering), packaging and filling: detailed studies of each individual packaging process are necessary to ensure the driest conditions, and therefore the maximum life of the product without deterioration.

- Cold stores: the ingress of moist air into these environments can cause condensation and ice formation in both products and facilities.

- Clean rooms: both in clean Rooms and in research and production facilities, moisture is a variable which must be controlled. We have equipment with characteristics capable of treating and filtering air efficiently in conditions down to -70°C dew point.

DFLEX

DFLEX desiccant dehumidifiers are very similar in operation to the DFRA desiccant rotor dehumidifiers. They are also based on a high-performance silica gel desiccant rotor for water vapor retention but have a higher flow rate and drying capacity. In addition, these desiccant dehumidifiers are characterized by a modular and flexible construction which makes them a perfect choice for air dehumidification in a multitude of applications.

- Drying capacities from 51 to 152 kg/h (*) and dry air flow rates from 7,500 to 24,000 m3/h.

- Highest drying capacity with high reliability.

- Versatile range with great adaptability to special requirements and a wide variety of options.

- Easily adaptable to be combined with air conditioners.

DFLOW

Watch video: Fisair DFLOW Series

Some industrial processes require spaces with low or no humidity levels in order to guarantee 100% product properties and manufacturing success. DFLOW air dehumidifiers are available for this type of process.

Fisair has designed its range of DFLOW dehumidifiers in order to cover these humidity conditions impossible to reach by any other type of dehumidifier. These dehumidifiers are able to reach humidity conditions of -70ºC dew point (0.002 grams of water per kg of dry air) with high operability and minimum energy consumption.

Features of the DFLOW series air dehumidifiers:

- Self-supporting structures, made of steel and plastic-coated panels for excellent sealing and easy cleaning.

- Easy access to the interior for maintenance and cleaning, with important safety considerations.

- High efficiency dual rotor system for fast set point adjustment without dependence on outside air conditions.

- Energy recovery, to recover heat from the thermal inertia of the rotor.

- State-of-the-art components make the units an excellent system for controlling the required air parameters.

- Expert Control System for constant performance monitoring and supervision of the unit, optionally remotely.

Contact your local TBCo branch location to learn more about these products and others to address pharmaceutical industry applications.